Why is the resistance value of aluminum shell resistance fluctuating like the stock market?

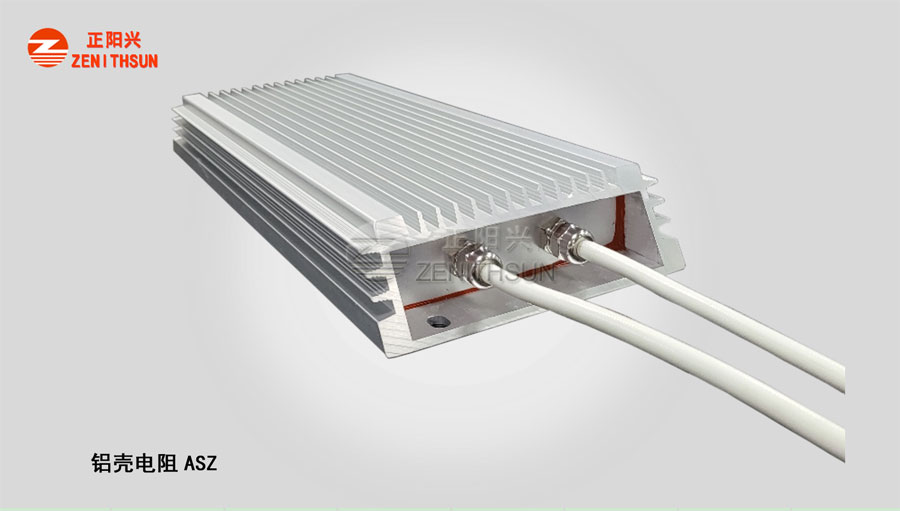

Aluminum shell resistor, also known as aluminum shell resistor, aluminum shell resistor. According to the use of different occasions, also known as brake resistance, brake resistance, precharge resistance or aging resistance and so on. Often hear a lot of different customer friends feedback, the same is the trapezoidal aluminum shell resistance, the same power and resistance value, resistance in the work why always meet resistance value up and down, change a lot?

Here we will explain to you why some aluminum shell resistance with stable performance, and some aluminum shell resistance in the work of the value of the same as the stock market fluctuations big reason!

The common silvery white trapezoidal aluminum shell resistors are made of industrial type 6063 aluminum shells. As we know, there are many factors that affect the performance of resistors, such as the size of the resistor design, the quality selection of various materials, the degree of process control, and the use environment, which will affect the working state of resistors.

The aluminum shell is used to help heat dissipation. The larger the area that contacts the air, the faster the heat dissipation. The groove on the surface of the aluminum shell is also a way to increase the heat dissipation. Therefore, the thickness, width and length of the aluminum shell all determine the speed of heat dissipation when the resistance is working, and thus determine the surface temperature of the resistance when it is working. The lower the temperature, the more stable the resistance, the better the performance! Some manufacturers because of low transaction price, limited profit, choose a small volume as a high power, or choose thin aluminum shell without weight, is also one of the reasons that affect the resistance performance of aluminum shell.

(Aluminium resistor/Aluminium resistor)

In addition to the aluminum shell, the most important is the main part of the internal resistance core - winding wire. Woven wire has KangCu alloy wire, nickel chromium alloy wire, iron chromium alloy wire, Kama wire, the price of more than 20 to more than 300 per kilogram. The correct selection of winding wire determines whether the resistance can withstand the service conditions required by customers. That is, under a certain current or a certain voltage, whether the resistance can work stably for a long time or under the peak current and voltage, whether the resistance can show good impact capacity. High quality alloy wire, low temperature coefficient, stable material performance, and we Zhengyangxing selected use higher than the traditional market 1.2 times of high quality alloy resistance wire uniform winding resistance core, so that it is more impact resistance, higher performance, higher stability.

The second is the choice of internal organosilicate quartz sand! Quality quartz sand is high purity, high density, high whiteness, low impurities of the original sand quartz sand, so that the resistance has high sealing, high insulation, high heat dissipation, high seismic characteristics; The inferior quartz sand is yellow, and the impurities are many, the particles are large, the density is small, and the filling effect has not reached a good seal and insulation. This is also our Zhengyang Xing company's aluminum shell resistance can withstand all aspects of the test.

In addition, there are some small accessories and high temperature line options. Some aluminum shell resistance in the hand, the skin is allergic and itchy, which is also the reason for choosing inferior high temperature wire. Our factory aluminum shell resistors all use high quality high temperature resistant 200℃ silica gel braided wire, no pilling, no allergy, through professional equipment welding terminals, there will be no fall off, no deformation phenomenon.

All material selection in place, is the process control. Rigorous process, can ensure the yield and consistency of products! Zhengyang Xing has been implementing the IATF 16949 automotive quality system requirements, which is one of the fundamental reasons for our foothold in the market.

In short, the market of aluminum shell resistance is diverse, if you pay attention to quality, choose a reliable manufacturer is very important!

Recommended information

- 正阳兴生产的负载箱应用的领域和特点!

- ZENITHSUN Production Site-1

- ZENITHSUN Production Site-2

- ZENITHSUN Production Site-3

- ZENITHSUN Production Site-4

- Load Bank Assembly Site -1

- Load Bank Assembly Site -2

- ZENITHSUN Load Banks Assembly Site-3

- Load Banks Batch Assembly Site-4

- Load Bank Assembly Site -5